0086-18695891045

Time : 2023-03-24

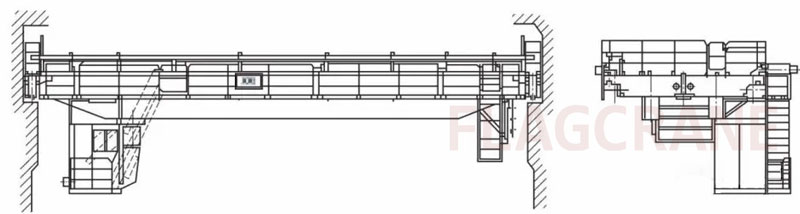

The traditional bridge crane consists of four parts: bridge frame (Figure 1-1), crane travelling mechanism (Figure 1-2), trolley assembly (Figure 1-3), and electrical appliances. These components and mechanisms all have a notable feature: planar layout, loose mechanism, larger space occupation, heavy structure, all parts of the mechanism have independent special-purpose bearing supports, and the appearance is ugly.

The bridge structure design of the traditional bridge crane is relatively complicated, and the manufacturing process is simple. The main girder mainly adopts the middle rail box girder structure. Only for large-tonnage cranes, the full-deviation rail or half-deviation rail box girder structure is used. The effective gauge of the trolley is relatively smaller. , will increase the self-weight of the trolley, and the track of the trolley adopts special steel rails, which are generally fixed and welded on the upper cover of the main beam by a pressure plate. The end beam is inserted between the upper and lower cover plates at both ends of the main beam, and connected by welding, so that the end beam and the main beam become an integral rigid structure, which can bear large bending moment and shear force. The end girder not only bears the vertical shear pressure caused by the self-weight of the bridge frame and the maximum lifting weight, but also always bears the force couple in the direction of the main girder mid-span. This couple is balanced by the vertical deflection of the main girder, so that the wheels on the end girder always The lateral force deflected toward the mid-span direction of the main girder and the crane wheels increase the possibility of deviation and rail rubbing, and it is easy to cause the crane to run skewed and the crane wheels to gnaw the rails.

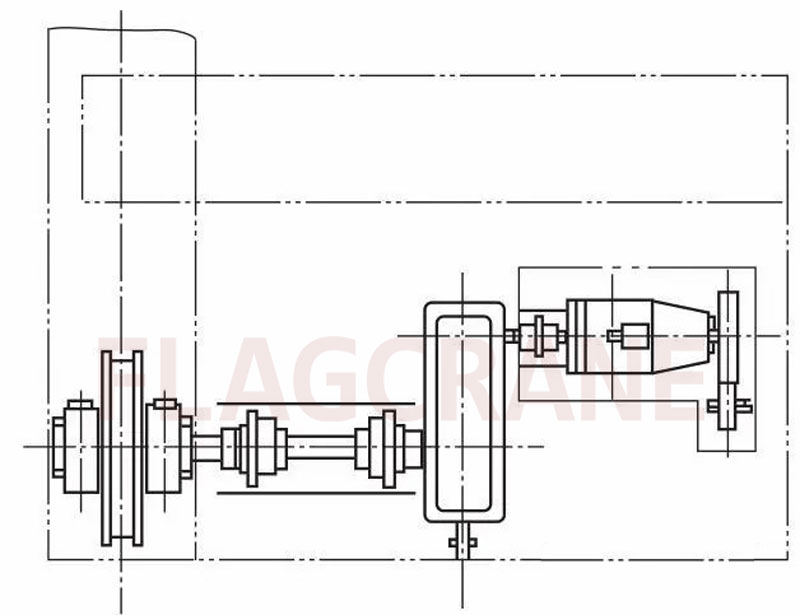

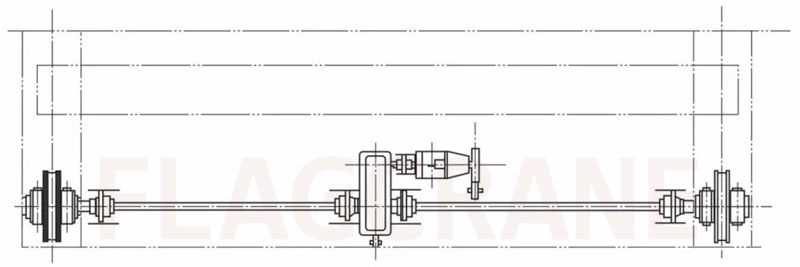

The operating mechanism of the crane is generally arranged in the way of centralized drive and separate drive (Figure1-4 & Figure1-2). Concentrated drive is an old drive type, and it is generally no longer used now; separate drive has opposite side drive and four-corner drive. Whether it is centralized driving or separate driving, it takes up a lot of space, the assembly precision of the mechanism is low, and it is not convenient for transportation and assembly. It is a relatively cumbersome mechanism.

The components of the crane operating mechanism (separately driven) are welded on the walking platform of the bridge frame by independent supports. The separated YZR winding motor passes through half-tooth couplings, floating shafts, brakes, and soft-toothed horizontal reducers ( Or the reducer with medium hard tooth surface) drives the driving wheel set with angular bearing housing. Because the floating shaft is long, it often affects the transmission of the crane due to the vibration caused by the load deformation of the bridge frame, and in severe cases, it also produces relatively large noise. The angular bearing box that fixedly supports the wheel has low assembly precision, a very crude structure, and a relatively short service life.

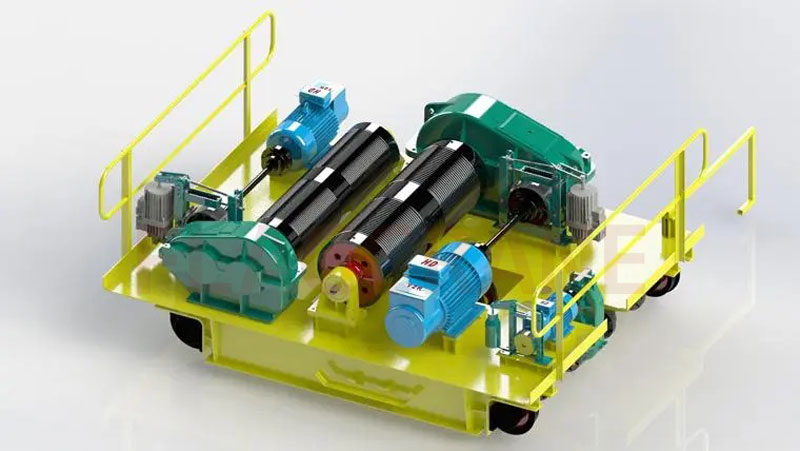

A notable feature of the traditional bridge crane trolley is that each transmission part of the trolley is supported by an independent special support, resulting in a super static structure arrangement, low transmission accuracy and efficiency, and a bulky structure. The parts of the hoisting mechanism and the running mechanism are arranged on the small frame of the plate structure, the structure is stressed, and the force on the four corners of the wheel is extremely unbalanced, which often makes the pressure of the active wheel close to several times that of the passive wheel, resulting in accidents. The lifting mechanism is loose, occupies a large volume, and has a high overall height. The structure and mechanism cannot be fully utilized, the waste of materials is very serious, the processing and manufacturing are complicated, the assembly accuracy is low, the structure is deformed seriously, and the weight of the trolley is heavy, which indirectly increases the structural weight of the main beam.

The lifting mechanism is driven by a separate YZR winding motor through a half-tooth coupling, a floating shaft, a brake, and a horizontal reducer with soft tooth surfaces (or a reducer with medium-hard tooth surfaces). The reel winds into the movable pulley of the hook group through the wire rope, goes up to the fixed pulley of the fixed pulley group, and then winds down to the movable pulley of the hook group (the number of times of up and down is determined according to the magnification), and winds back to the reel to form a winding closed loop. For slow-speed and large-tonnage cranes, the transmission ratio of the reducer is relatively large, and only open gear transmission can be used, which takes up more space, and the problem of oil leakage is difficult to overcome. The brake adopts wheel brake, the assembly precision is low, and the brake wheel is easy to wear. Generally, a long floating shaft is connected to the motor to reduce the eccentric rotation during work.

The reel group is generally connected with the reducer by a gear plate, resulting in a large assembly gap, low assembly accuracy, and low transmission efficiency. The fixed pulley block consists of a row of pulleys distributed on the fixed pulley shaft. The pulley shaft is parallel to the drum shaft. For large-tonnage cranes, the number of pulleys is large, the efficiency of the lifting mechanism is reduced, and the power of the motor is increased in disguise. The width of the fixed pulley block is particularly large. , The space occupied increases, which also leads to a wider lifting mechanism and an increase in the gauge of the trolley.

A summary of traditional bridge cranes has the following characteristics.

(1) The quality of mechanism parts is poor, the appearance is bulky and rough, and the machining accuracy is low. Because the price is too low, the quality of heat treatment is difficult to guarantee, the cost is increased, and the appearance is ugly.

(2) The trolley is arranged in a plane, and the lifting mechanism is scattered on the plane of the trolley frame. The pressure of the trolley wheels is uneven. Due to the structure itself, the maximum wheel pressure of the wheels is relatively large, which is not artificially designed, and the designed wheel diameter is also relatively large. big.

(3) The components of the lifting mechanism are single independent components, and special seats are welded on the plane of the trolley frame, resulting in large assembly errors.

(4) The end girder of the crane is a rigid end girder, which is welded together with the main girder. It bears bending moment and shear stress, and the force is complex. The wheel pressure of the crane is uneven, the maximum wheel pressure is large, and the wheel diameter is large.

(5) After the bridge frame is assembled and disassembled, it is often difficult to meet the installation requirements on site. The structure is seriously deformed, and the surface paint of the bridge frame is easily damaged during repair. There is pyrotechnic work from assembly to on-site installation by the user, and the appearance of the crane is very poor.

(6) The distance from the track surface of the crane to the highest point of the trolley is relatively large, and the civil construction cost of the plant is relatively large.

(7) The limit distance from the centerline of the main and auxiliary hooks of the trolley to the centerline of the crane track is relatively large, and the effective working space area is relatively small.

(8) The calculation of the design of the small frame is complicated, and there is a lot of waste of materials.

(9) The transportation of the whole vehicle is inconvenient, and it is often super wide and super high.

Flagcrane have a professional technical team, which can design and produce standard and non-standard crane hoist and spare parts. If there are other special requirements. it can be customize according to user needs and negotiate by both parties.